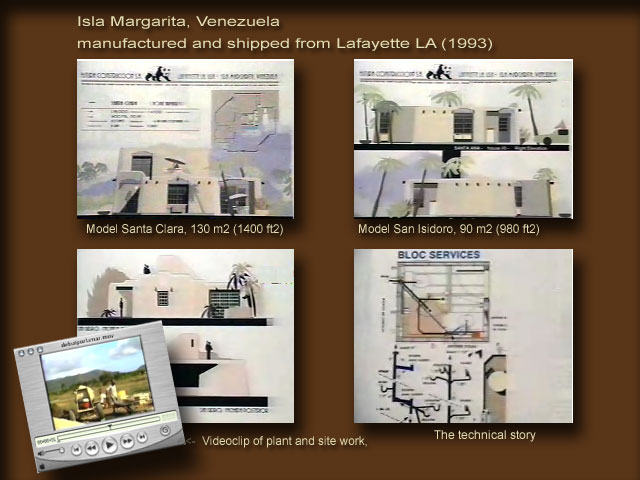

Retirement clusters spread on a grand set of dunes by a lovely beach. On top, north American clusters where each owner is fully isolated from his neighbors in spite of the fact that they share a common plumbing and utilities core connection. Very economical, they provide privacy and comfort without wasting land use and grounds utilities.

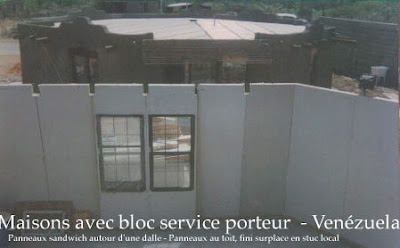

In that project, the same basic arrangement is treated in the local idiom by simply changing the roof for synthetic grass over a membrane, also using local craftmen to decorate the panels prior to their erection. These are confined on a small island in the project were artists are invited to stay to create a restful haven for tourists and retirees, having flute players and teachers of Tai Chi and martial arts do demonstrations.