In the later half on the seventies, Poirier's familiarity with production systems brought him to the booming RV business. Starting with tent trailers, he graduated to camping trailers and then motor homes. Finally, a revolutionnary mobile home building technique was developed by a team led by him as chief designer with Bellevue Industries. These ho,es were made up of only 4 wall panels, one roof panel and one floor panel, forming a box that was both rigid and insulated. The world's largest press was built 25m x 5m x 5m deep, a giant concrete and steel 'toaster' capable of 9 million pounds of pressure, enough to contain these giant panels while they were being injected with polyurethane foam.

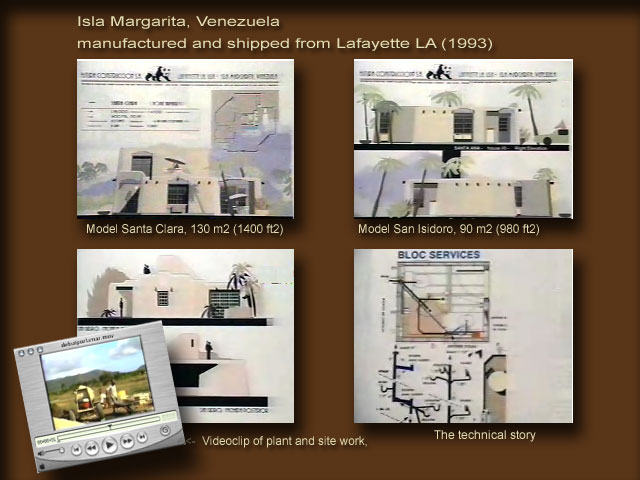

This box construction allowed for maritime shipping without deconsolidation of the structure. Export to 3 continents of prefab homes, double and triple wide, was the next step. Algeria, Crete, France, and several other countries have received those house. Poirier's foray into a field that quickly became his own was the first of a large export effort from Canada.

The Institute ows a lot to those intense five years that in the end gave birth to the Archimede concept. Poirier was rewarded by his peers as the architect who did the most for the housing export trade.

First was a vertical wedge action pair of presses designed by us in 1980.

First was a vertical wedge action pair of presses designed by us in 1980.

.

.